High-Pressure Homogenizers: Optimizing Liposome and Nanomaterial Production

High-pressure homogenizers play a vital role in controlling particle size and achieving uniform dispersion, especially in liposome and nanomaterial production. These systems are essential across industries like pharmaceuticals, cosmetics, and food, where precise particle size is crucial for product performance.

Efficient Liposome Production

High-pressure homogenizers are highly effective in breaking lipid-water mixtures into stable, smaller liposomes. This process ensures the encapsulation of active compounds such as drugs, allowing for more targeted delivery. The resulting liposomes can range from 50 nm to several micrometers, depending on the application.

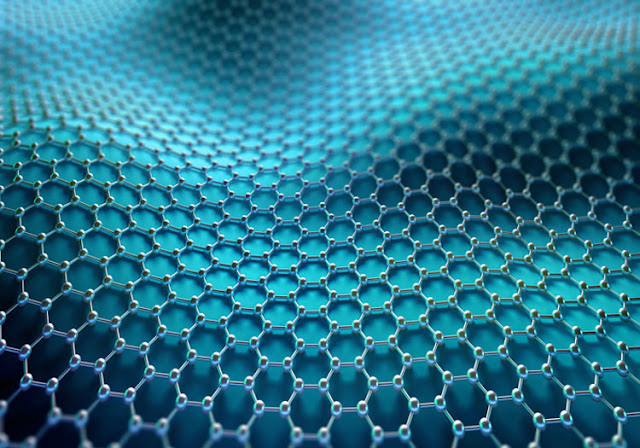

Nanomaterial Processing: Precision for Advanced Applications

In nanomaterial production, high-pressure homogenizers are used to reduce larger materials like carbon nanotubes and graphene into nanoparticles. This method enhances dispersion, surface characteristics, and stability, all critical factors for applications in drug delivery, energy storage, and coatings.

Scalable and Flexible for Both Research and Industry

One of the strengths of high-pressure homogenizers is their adaptability. They can be used for both small-scale laboratory work and large-scale commercial production. The UltraGenizer high-pressure homogenizer is designed to handle both liposome production and nanomilling, offering customizable pressure and flow rates to meet specific needs.

Consistent Performance with High-Pressure Homogenizers

High-pressure homogenizers are essential for producing liposomes and nanomaterials with controlled particle size, superior dispersion, and enhanced stability. Their scalability makes them ideal for both experimental and industrial-scale production.

Key Advantages:

- Precise Control Over Particle Size

- Flexible for Research and Commercial Production

- Improved Dispersion and Stability

Related Articles

Using NanoGenizer High Pressure Homogenizers for Nanomaterials

Liposome Extruders: Functions, Mechanisms, and Types

Liposome Processing: High Pressure Homogenizer vs Liposome Extruder.

3Questions to Ask When Considering a Liposome Extrusion Option

High Pressure Homogenization vs Sonication: Which is Better for Your Liquid Formulation?

How to choose a High Pressure Homogenizer?

Microfluidic High Pressure Homogenizer vs Conventional High Pressure

What is high pressure homogenizer, how does it work?

Advantages of UltraGenizer High Pressure Homogenizer?

Using High-Pressure Microfluidic Homogenizers for Micro and Nano Emulsions

Microjet NanoGenizer and Micromix MixGenizer: the next generation homogenizer for nanomaterials

Comments

Post a Comment