How does NanoGenizer High-Pressure Homogenizer work?

The NanoGenizer Core Processing Unit

The NanoGenizer is a laboratory scale high-pressure homogenizer. There are two segments of the NanoGenizer, the power unit and the core processing unit. The core processing unit is where homogenization occurs.

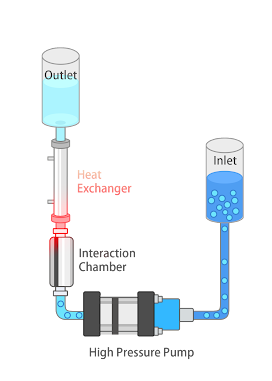

Before homogenization, the user places the sample in the inlet reservoir. Genizer offers a variety of options for your inlet reservoir. You may prefer a smaller or larger inlet reservoir depending upon the size of your sample. In addition to stainless steel, we offer plastic syringes and glass inlet reservoirs. Genizer also offers a variety of outlet reservoirs, where the sample goes after processing. You may prefer to use a jacketed glass cylinder, which you can connect to a laboratory chiller circulator for temperature control. Schematic of the NanoGenizer core processing unit,with the inlet reservoir, high-pressure pump, interaction chamber, heat exchanger and outlet reservoirFor small, valuable samples, the syringe option is best. You can hook a Luer hose up to the outlet valve and place the other end in the inlet reservoir to circulate your sample through the core processing unit multiple times. Most samples need 5-10 passes through the diamond interaction chamber (DIXC) to be fully homogenized. Alternatively, you can place the Luer hose into any outlet receptacle in your lab.

The inlet and outlet valve ensures your sample travels the correct direction through the core processing unit. The inlet valve is a one-way valve that allows the sample to enter but not exit. The outlet valve is also a one-way valve and allows the sample to exit but not enter. The sample travels through the inlet valve, into the-high pressure cylinder, and out the outlet valve into the Diamond Interaction Chamber.

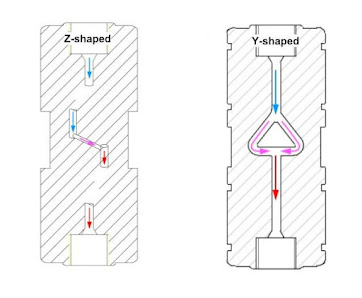

The Diamond Interaction Chamber is where homogenization occurs. The chamber can be either Z-shaped or Y-shaped. In the Y-shaped diamond interaction chamber, the sample splits into two streams. Where the two streams collide, forces like high shear and cavitation homogenize the sample. In the z-type chamber, instead of the sample colliding with itself, it collides with the wall of the chamber. After homogenization, the particles are smaller and more uniform and liquids that would normally be immiscible can be mixed.Diagram of the path of liquid Z-shaped and Y-shaped interaction chambers

Genizer's Diamond Interaction Chamber can come with a cooling option. Additionally, if you need more cooling properties, Genizer offers a real-time heat exchanger. This method of cooling is superior for thermally unstable samples.

The NanoGenizer offers low minimum volume, low dead volume and temperature control options. Please click here for more information on the NanoGenizer.

Related Articles

Using NanoGenizer High Pressure Homogenizers for Nanomaterials.

Liposome Extruders: Functions, Mechanisms, and Types

Liposome Processing: High Pressure Homogenizer vs Liposome Extruder

High Pressure Homogenization vs Sonication: Which is Better for Your Liquid Formulation?

How to choose a High Pressure Homogenizer?

Benefits of Ultra High Pressure Homogenizer

Microfluidic High Pressure Homogenizer vs Conventional High Pressure Homogenizer, How to Choose?

Comments

Post a Comment