Valve Type VS. Microfluidic High Pressure Homogenizer, Which is Better For Your Application?

Valve-Type High-Pressure Homogenizer vs. Microfluidic Homogenizer: Which Is Better for Your Application?

High-pressure homogenization is essential across various industries, including pharmaceuticals, biotechnology, and food processing, where particle size reduction and stable emulsion formation are critical. Among the technologies available, valve-type high-pressure homogenizers and microfluidic homogenizers are two popular options, each offering unique advantages. In this article, we will compare these two technologies to help you determine which is best suited for your specific application.

Understanding Microfluidic Homogenizers

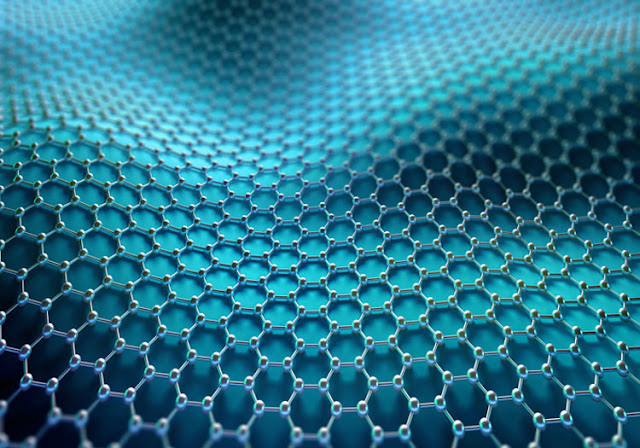

Microfluidic homogenizers are high-pressure systems that utilize fixed geometry microchannels instead of valves to create a consistent shear rate on liquids. This innovative design allows for precise control of fluid dynamics, leading to effective particle size reduction while minimizing energy loss as heat. Microfluidic homogenizers are ideal for applications that demand high precision, such as creating fine emulsions or suspensions.

Key Comparisons

Shear Rate

- Microfluidic Homogenizers: These systems maintain a higher and more consistent shear rate, which is crucial for achieving uniform particle sizes and stable emulsions.

- Valve-Type Homogenizers: Traditional valve-type homogenizers rely on valves to restrict flow and build pressure, often resulting in variable shear rates that can affect the quality of the final product.

Energy Efficiency

- Microfluidic Homogenizers: One of the standout advantages is their energy efficiency. These systems convert less process energy into heat, reducing the risk of thermal effects that could compromise the integrity of temperature-sensitive materials.

- Valve-Type Homogenizers: The mechanical restrictions imposed by valves tend to generate more heat, which can be detrimental for applications involving heat-sensitive compounds.

Ease of Use

- Microfluidic Homogenizers: Operating and cleaning these systems is generally more straightforward. Their design allows for easier maintenance, significantly reducing downtime between batches.

- Valve-Type Homogenizers: In contrast, valve-type systems often require manual disassembly and cleaning of valves, which can be labor-intensive and time-consuming.

Particle Size Control

- Microfluidic Homogenizers: These devices excel in producing smaller droplet sizes, making them particularly suitable for applications requiring ultra-fine emulsions or suspensions.

- Valve-Type Homogenizers: While they can reduce particle sizes, valve-type homogenizers may not achieve the same level of precision, especially for ultra-fine applications.

Overall Performance

- Microfluidic Homogenizers: For high-value or advanced materials where precise particle size and distribution are critical, microfluidic homogenizers are often the preferred choice. Their ability to maintain consistent shear rates and minimize thermal effects enhances the quality of the final product.

- Valve-Type Homogenizers: These systems are effective for general emulsification and can handle larger batch sizes but may fall short in meeting the stringent requirements of advanced applications.

|

Choosing between valve-type high-pressure homogenizers and microfluidic homogenizers largely depends on your specific application requirements. If your focus is on high precision, energy efficiency, and effective particle size control—especially for high-value materials—microfluidic homogenizers may be the best option. Conversely, if you require a cost-effective solution for general emulsification or larger batch processing, valve-type homogenizers can provide satisfactory performance.

By understanding the differences between these two technologies, you can make an informed decision that enhances your production processes and improves product quality. Whether you're looking to invest in new equipment or upgrade existing systems, selecting the right homogenization technology is key to achieving optimal results in your application.

Related Articles

Using NanoGenizer High Pressure Homogenizers for Nanomaterials

Liposome Extruders: Functions, Mechanisms, and Types

Liposome Processing: High Pressure Homogenizer vs Liposome Extruder.

3Questions to Ask When Considering a Liposome Extrusion Option

High Pressure Homogenization vs Sonication: Which is Better for Your Liquid Formulation?

How to choose a High Pressure Homogenizer?

Microfluidic High Pressure Homogenizer vs Conventional High Pressure

What is high pressure homogenizer, how does it work?

Advantages of UltraGenizer High Pressure Homogenizer?

Using High-Pressure Microfluidic Homogenizers for Micro and Nano Emulsions

Microjet NanoGenizer and Micromix MixGenizer: the next generation homogenizer for nanomaterials

Comments

Post a Comment