Graphene: A Material Marvel

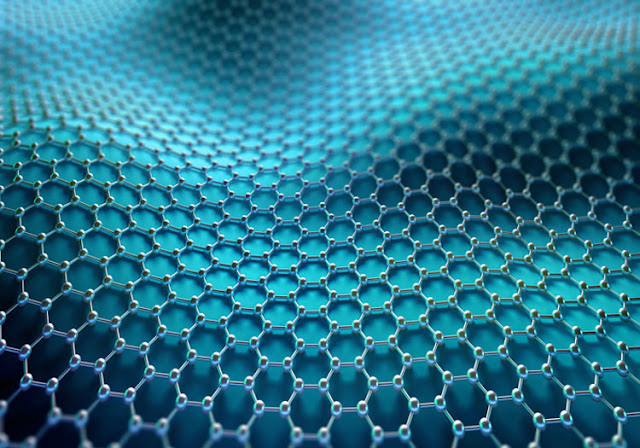

Graphene, discovered in 2004, is a thin sheet of carbon atoms arranged in a hexagonal pattern. Its outstanding properties and many potential uses make it a frontier material in science. Here, we discuss what graphene is, its amazing advantages, its various applications in different fields, and how high-pressure homogenization is used to process it.

What is Graphene?

Graphene is often hailed as a wonder material due to its extraordinary properties. With a tensile strength over 100 times greater than steel and excellent electrical and thermal conductivity, graphene is one of the strongest, lightest, and most versatile materials known to man. Its unique atomic structure gives it remarkable flexibility, transparency, and chemical stability, making it suitable for a wide range of applications across various industries.

Advantages of Graphene

The advantages of graphene are manifold and hold the promise of revolutionizing numerous technologies and industries. Here are some key advantages of graphene:

Exceptional Strength and Lightweight: Graphene's remarkable strength-to-weight ratio makes it ideal for applications where strength and durability are paramount, such as aerospace, automotive, and structural engineering.

High Electrical and Thermal Conductivity: Graphene exhibits unparalleled electrical and thermal conductivity, outperforming traditional materials like copper and silicon. This property makes it invaluable for use in electronics, energy storage, and thermal management systems.

Flexibility and Transparency: Graphene's flexibility and transparency enable its integration into flexible and transparent electronic devices, including bendable displays, touchscreens, and wearable electronics.

Chemical Stability: Graphene is highly resistant to corrosion and chemical degradation, making it suitable for use in harsh environments and in applications where durability is essential, such as coatings and protective layers.

Biocompatibility: Graphene's biocompatibility and ability to interact with biological molecules make it promising for various biomedical applications, including drug delivery systems, biosensors, and tissue engineering.

Applications of Graphene

Graphene's exceptional properties have led to its exploration and adoption in various industries and technologies.

Electronics: Graphene's high electrical conductivity and transparency make it ideal for use in electronics, including transistors, touchscreens, and flexible displays.

Energy Storage: Graphene's large surface area and high electrical conductivity make it an excellent candidate for energy storage devices such as batteries and supercapacitors, enabling faster charging and longer-lasting energy storage solutions.

Composite Materials: Graphene can be incorporated into composite materials to enhance their mechanical strength, conductivity, and thermal properties, making them lighter, stronger, and more durable.

Biomedical Applications: Graphene's biocompatibility and unique properties make it promising for various biomedical applications, including drug delivery systems, biosensors, and tissue engineering.

Processing Graphene with High-Pressure Homogenization

High-pressure homogenization stands out as one of the most promising methods for processing graphene. High-pressure homogenizers, like the NanoGenizer, operate by producing high flow velocity through a small orifice, employing a specially designed internal fixed geometry under ultra-high pressure (up to 60,000 psi). Throughout the homogenization process, various physical, chemical, and structural changes occur. As a result, a homogeneous suspension is achieved at the nanoscale. Specifically, high-pressure homogenizers are utilized to exfoliate graphite flakes or graphite oxide (GO) into individual or few-layer graphene sheets.

The process commences by dispersing graphite or GO in a suitable solvent, such as water or organic solvents. Subsequently, the suspension undergoes high pressure as it passes through the homogenizer. The intense shear forces and turbulence generated during high-pressure homogenization effectively separate the layers of graphene, resulting in a dispersion of graphene flakes or sheets in the solvent.

Genizer High pressure homogenizer

Advantages of High-Pressure Homogenization for Graphene Processing

High-pressure homogenization offers several advantages for processing graphene:

Scalability: High-pressure homogenizers are available in various sizes and configurations, allowing for scalable production of graphene dispersions from small laboratory-scale batches to large industrial-scale quantities.

Control: The pressure and other process parameters can be controlled to optimize the exfoliation process and achieve desired properties of the graphene dispersion, such as particle size and distribution.

Efficiency: High-pressure homogenization can achieve high levels of exfoliation efficiency, producing high-quality graphene dispersions with minimal defects or damage to the graphene sheets.

Versatility: High-pressure homogenizers can be used with a wide range of starting materials and solvents, making them suitable for exfoliating different types of graphene precursors and tailoring the properties of the resulting graphene dispersions for specific applications.

Graphene, with its remarkable properties and potential applications, represents a new frontier in materials science. With continued research and development efforts, graphene-based technologies have the potential to transform industries, improve quality of life, and address some of the most pressing challenges facing society today.

Related Articles

Using NanoGenizer High Pressure Homogenizers for Nanomaterials

Liposome Extruders: Functions, Mechanisms, and Types

Liposome Processing: High Pressure Homogenizer vs Liposome Extruder.

3Questions to Ask When Considering a Liposome Extrusion Option

High Pressure Homogenization vs Sonication: Which is Better for Your Liquid Formulation?

How to choose a High Pressure Homogenizer?

Microfluidic High Pressure Homogenizer vs Conventional High Pressure

Homogenizer, How to Choose?

What is high pressure homogenizer, how does it work?

Advantages of UltraGenizer High Pressure Homogenizer?

Using High-Pressure Microfluidic Homogenizers for Micro and Nano Emulsions

Microjet NanoGenizer and Micromix MixGenizer: the next generation homogenizer for nanomaterials

Comments

Post a Comment