Use of High Pressure Homogenization for Nanotubes

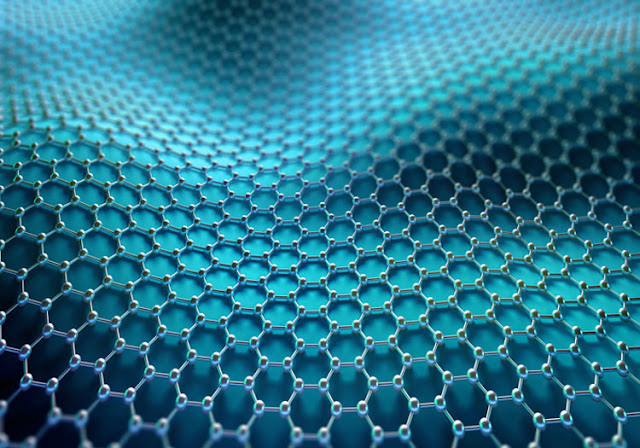

What are carbon nanotubes?

Carbon nanotubes (CNTs) are tiny, hollow cylindrical tubes made of carbon atoms, essentially rolled-up sheets of graphene, with diameters measured in nanometers, possessing unique electrical, mechanical, and thermal properties due to their unique structure at the nanoscale level; they are known for their exceptional strength, lightweight nature, and high conductivity, making them promising for various applications in technology and materials science.

Due to the unique properties of carbon nanotubes (CNTs), their use extends to various applications in field emission, energy storage, biomedicine, industrial catalysts, adhesives, thermal materials. also due to their impressive properties of being both strong and incredibly lightweight, as well as being excellent conductors of heat and electricity.

Challenges in Carbon Nanotube Dispersion

Due to strong Van der Waals forces, CNTs tend to cluster together, making it difficult to achieve stable and uniform dispersions. Traditional methods such as sonication often fall short, especially when scaling up for industrial applications.

High-Pressure Homogenization: A Solution For Carbon Nanotube Dispersion

HPH offers a powerful solution for dispersing CNTs by applying intense pressure (up to 45,000 psi) to break up CNT aggregates. During the process, a fluid containing CNTs is forced through a narrow orifice at high speeds, generating extreme shear forces that separate the nanotubes and create a uniform dispersion. The Genizer high-pressure mcirofluidic homogenizer is a notable example of equipment designed to achieve this level of dispersion effectively.

Advantages of HPH for CNT Processing

The primary advantage of HPH is its ability to achieve consistent dispersion across large volumes. This uniformity is crucial for applications where the precise arrangement of CNTs is necessary, such as in nanocomposites, electronics, and coatings. Additionally, HPH enables the scaling of CNT processing, making it feasible for both research and industrial production.

High-pressure homogenization has revolutionized the way carbon nanotubes are processed, ensuring efficient, scalable, and consistent dispersions. As industries continue to explore CNTs' potential, HPH will play a key role in enabling their full application across various fields.

Related Articles

Using NanoGenizer High Pressure Homogenizers for Nanomaterials

Liposome Extruders: Functions, Mechanisms, and Types

Liposome Processing: High Pressure Homogenizer vs Liposome Extruder.

3Questions to Ask When Considering a Liposome Extrusion Option

High Pressure Homogenization vs Sonication: Which is Better for Your Liquid Formulation?

How to choose a High Pressure Homogenizer?

Microfluidic High Pressure Homogenizer vs Conventional High Pressure

Homogenizer, How to Choose?

What is high pressure homogenizer, how does it work?

Advantages of UltraGenizer High Pressure Homogenizer?

Using High-Pressure Microfluidic Homogenizers for Micro and Nano Emulsions

Microjet NanoGenizer and Micromix MixGenizer: the next generation homogenizer for nanomaterials

Comments

Post a Comment