Liposome Processing: High-Pressure Homogenizer or Liposome Extruder?

Choosing between a high-pressure homogenizer or a liposome extruder for your liposomes

Choosing between a high-pressure homogenizer or a liposome extruder for your liposomes can be a daunting task. Both devices have their advantages and can process liposomes, but the choice ultimately depends on your specific application requirements.

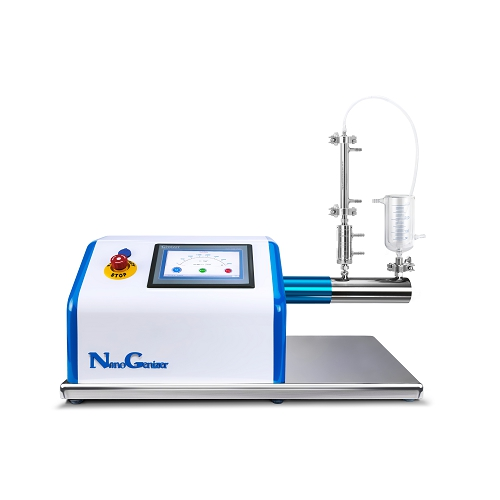

Option 1:High-Pressure Homogenizer

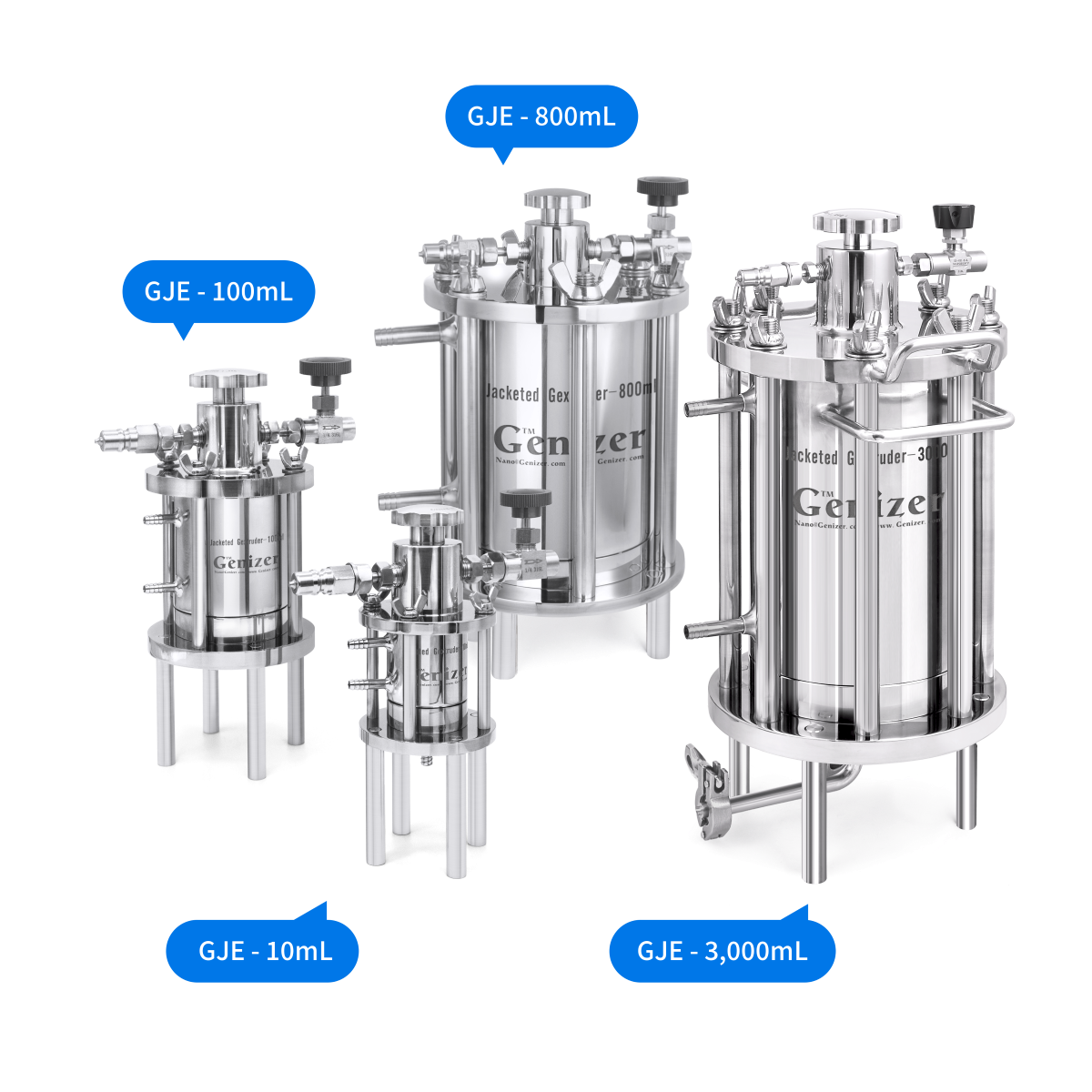

Option 2: Liposome Extruder

If accuracy is a priority for your liposome preparation process, a jacketed liposome extruder might be the better option for you. Liposome extruders have a narrower size distribution of liposomes after processing, allowing for more precise control over the final liposome product. Additionally, the adjustable membrane pore size in a liposome extruder allows for greater control over the diameter of liposomes after processing. Our liposome extruders are also more economical than high-pressure homogenizers, making them a great option for researchers on a budget. Finally, our jacketed liposome extruders are gas powered, reducing the amount of electricity needed to run them.

Option 3: Combination of High-Pressure Homogenizer and Liposome Extruder

In summary, the choice between a high-pressure homogenizer or a liposome extruder depends on your specific application requirements. If you need a faster flow rate and improved efficiency, the high-pressure homogenizer is the way to go. If accuracy and affordability are a priority, a liposome extruder might be the better option. And if you want to take advantage of the benefits of both, consider using a liposome extruder in conjunction with a high-pressure homogenizer.

For more information, pls visit Genizer LLC.

Comments

Post a Comment