How to choose a high pressure homogenizer for your applications?

High-pressure

homogenizers play a pivotal role in

various domains, including scientific research, pharmaceutical manufacturing,

cosmetics, and food processing. Opting for an appropriate high-pressure

homogenizer is crucial to ensure optimal experimental outcomes and resource

efficiency. Here are several key factors to consider when selecting the most

suitable high-pressure homogenizer:

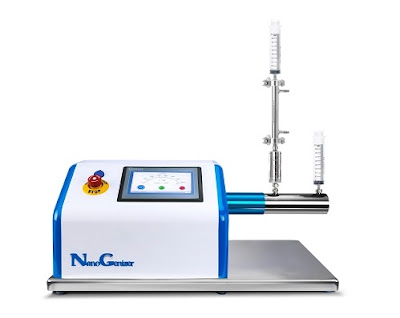

Genizer High Pressure Microfluidic Homogenizers

1. Homogenization

Pressure: Maximizing Performance by Optimizing Pressure

Increasing

pressure allows for finer particle size reduction, enabling efficient

processing. Higher pressures accommodate a broader range of materials for

effective homogenization. For example, certain liquid emulsions require a

minimum pressure of 15,000 psi to achieve sub-100nm homogenization, while

achieving nanoscale homogenization for pharmaceuticals, foods, and suspensions

with solid particles typically demands pressures exceeding 26,000 psi.

2. Minimal

Sample Volume: Enhancing Efficiency through Material Conservation

Minimizing

sample volume helps conserve expensive raw materials, especially considering

the high cost of specific pharmaceutical ingredients (several thousand dollars

per gram). Since experiments often involve multiple iterations, larger minimum

sample volumes lead to significant material waste.

3. Processing

Effectiveness: Achieving Nano-Level Precision and Uniform Particle

Size Distribution Desirable outcomes involve

attaining nanoscale particle size and ensuring uniform particle size

distribution. To address this, it is advisable to acquire a high-pressure

homogenizer equipped with a nano-level filtration extruder device, preferably

an inline extruder, to enhance processing effectiveness.

4. Cleaning

and Sterilization: Optimizing Maintenance and Sanitization

Some

high-pressure homogenizers offer convenient cleaning and sterilization

procedures. Prioritizing models that facilitate online cleaning and

sterilization is recommended.

5. Additional

Considerations: Noise, Safety, and Reputation

Evaluate

factors such as noise levels, safety features, and the reputation of the

homogenizer. Analyzing customer lists can provide insights into the popularity

and quality of a particular device.

6. Manufacturer

Validation:

Customer References and Supporting Evidence Request a

customer

reference list from homogenizer manufacturers to assess customer satisfaction.

Additionally, inquire about relevant research papers and achievements to

further evaluate the equipment's credibility.

By thoroughly considering these factors, potential users can make well-informed comparisons and select the most suitable high-pressure homogenizer based on their specific requirements.

Comments

Post a Comment