Microjet NanoGenizer and Micromix MixGenizer: the next generation homogenizer for nanomaterials

Microjet technology is a method for producing nanomaterials in high-pressure fluid jets, enabling the scalable and efficient production of nanomaterials. In the vast field of manufacturing, an 'industrial mother machine' refers to equipment crucial for producing other machines or products. Nanomaterials, key raw materials for various functional products, find broad applications, and the NanoGenizer Microjet Homogenizer is one such device widely used in the preparation of nano-drug formulations and various emerging nanomaterials, making it a leading industrial mother machine for next-generation nanomaterials. High-pressure Micromix technology is an extension of Microjet technology, where the Micromix MixGenizer High-Pressure Homogenizer generates nanomaterials by precisely controlling multiphase mixing. These two devices play fundamental and crucial roles in the production of advanced nanomaterials, holding significant importance in driving the entire field of nanotechnology.

1. Wide Applications in Nanomaterials

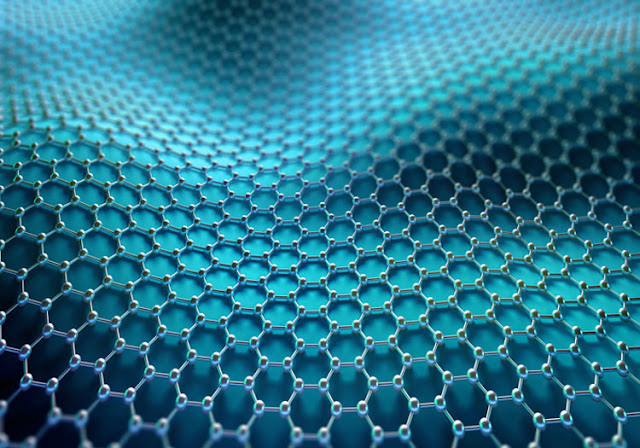

Nanomaterials include not only traditional nanoemulsions, liposomes, nanosuspensions, nanoparticles, and nanocrystals but also involve the preparation of new nanomaterials such as graphene, carbon nanotubes, and fuel cell catalysts. These nanomaterials are increasingly applied in various fields such as medicine, electronics, and energy, playing an undeniable role in driving technological innovation and progress.

Figure 1: Applications of Microjet Technology in the Nano Field

2. Critical Role in Manufacturing Technology

In the manufacturing process of nanomaterials, high-pressure Microjet Technology (NanoGenizer) and Micromix Technology (MixGenizer) have become key technologies for producing these nanomaterials. The emergence of these two technologies has brought revolutionary changes to the field of nanotechnology, making the preparation of nanomaterials more efficient and precise.

Figure 2: NanoGenizer High-Pressure Microjet Homogenizer

2.1 Features of Microjet NanoGenizer

NanoGenizer, renowned for its high-pressure microjet technology, is suitable for the batch production of efficient and high-precision nanomaterials. Its working principle is based on high-pressure and high-speed microjet flow, enabling the production of nanomaterials in a shorter time while ensuring the uniformity and stability of the materials. This technology particularly excels in the preparation of new nanomaterials, providing a solid foundation for breakthroughs in nanotechnology.

2.2 Unique Advantages of Micromix MixGenizer

MixGenizer, on the other hand, is characterized by its micromix technology, excelling in the precise mixing of different phases of materials and suitable for the preparation of complex nanomaterials. The introduction of micromix technology makes the proportions and mixing processes of different materials more controllable, ensuring the performance and characteristics of the final nanomaterials. The flexibility and precision of MixGenizer make it an indispensable key tool in the manufacturing of nanomaterials. In comparison to microjet technology, the MixGenizer can simultaneously handle aqueous and oil phases, generating more than two microjets through micromix principles, allowing for simultaneous generation of nanomaterials. In contrast, microjet technology equipment can only handle single-phase fluids.

|

Figure 3: MixGenizer High-Pressure Micromix Homogenizer

3. Applications and Advantages

These two technologies provide efficient and flexible solutions in the manufacturing of nanomaterials, playing a crucial role in driving the development of nanotechnology. The batch production capability of NanoGenizer makes large-scale applications possible, while the precise mixing technology of MixGenizer provides a solution for the preparation of complex nanomaterials. The continuous evolution and expanded applications of nanotechnology will heavily rely on the silent support of these two new-generation industrial mother machines.

4. Future Outlook

As nanotechnology continues to advance, Microjet NanoGenizer and Micromix MixGenizer, as industrial mother machines for nanomaterials, will continue to play critical roles. It is expected that in the future, these technologies will continue to innovate and upgrade to meet the demands of more complex nanomaterial preparations. Simultaneously, their application areas will expand into more emerging fields, contributing to greater advancements in technology and human well-being.

In summary, the emergence of Microjet NanoGenizer and Micromix MixGenizer marks a revolutionary leap in nanomaterial manufacturing technology. They not only play an irreplaceable role in manufacturing but also serve as key engines driving the development of nanotechnology. The continuous innovation of these two industrial mother machines will open up a broader future for the preparation of nanomaterials, bringing more surprises and transformations to human society.

Related Articles

Using NanoGenizer High Pressure Homogenizers for Nanomaterials

Liposome Extruders: Functions, Mechanisms, and Types

Liposome Processing: High Pressure Homogenizer vs Liposome Extruder.

3Questions to Ask When Considering a Liposome Extrusion Option

High Pressure Homogenization vs Sonication: Which is Better for Your Liquid Formulation?

How to choose a High Pressure Homogenizer?

Microfluidic High Pressure Homogenizer vs Conventional High Pressure

Homogenizer, How to Choose?

What is high pressure homogenizer, how does it work?

Advantages of UltraGenizer High Pressure Homogenizer?

Using High-Pressure Microfluidic Homogenizers for Micro and Nano Emulsions

Comments

Post a Comment