How does NanoGenizer High-Pressure Homogenizer work?

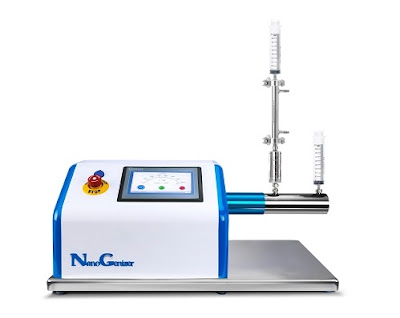

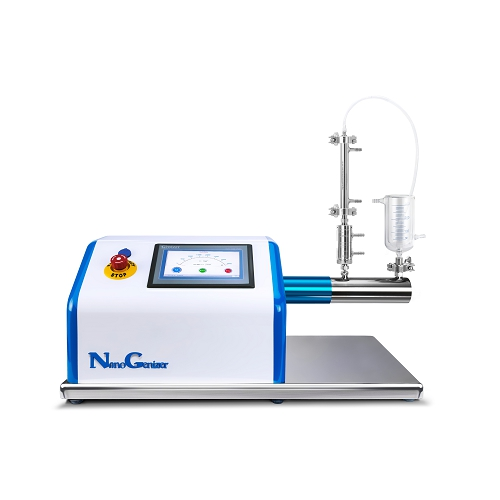

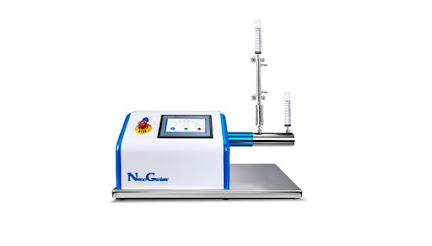

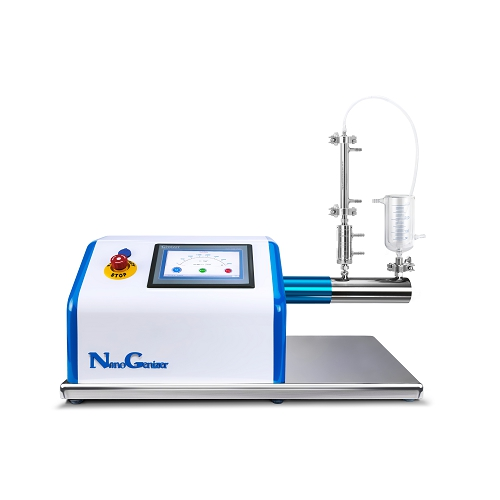

The NanoGenizer Core Processing Unit The NanoGenizer is a laboratory scale high-pressure homogenizer. There are two segments of the NanoGenizer, the power unit and the core processing unit. The core processing unit is where homogenization occurs. Before homogenization, the user places the sample in the inlet reservoir. Genizer offers a variety of options for your inlet reservoir. You may prefer a smaller or larger inlet reservoir depending upon the size of your sample. In addition to stainless steel, we offer plastic syringes and glass inlet reservoirs. Genizer also offers a variety of outlet reservoirs, where the sample goes after processing. You may prefer to use a jacketed glass cylinder, which you can connect to a laboratory chiller circulator for temperature control. Schematic of the NanoGenizer core processing unit,with the inlet reservoir, high-pressure pump, interaction chamber, heat exchanger and outlet reservoirFor small, valuable samples, the syringe option is b...