Energy efficient, 1/2 energy loss of the most homogenizers

Small (integrated design delivers the light weight and small dimensions)

Smart (programming control systems confer diligent functions: controlled inlet volume ± 0.1mL; auto stop with time/volume)

Silent (noiseless performance)

Strong (more than 150 mL/min at 30,000 psi)

CE compliant and RoHs compliant

| Specifications | | Catalog No. | NG-45K | NG-30K | NG-25K | NG-20K | NG-15K | | Flow Rate | 60mL/min | 100mL/min | 100mL/min | 150mL/min | 150mL/min | | Min. Sample | 5mL | 5mL | 5mL | 5mL | 5mL | | Max. Pressure | 45,000psi | 30,000psi | 25,000psi | 20,000psi | 15,000psi | | Dimensions(cm) | 70 × 36 × 30 | 70 × 36 × 30 | 70 × 36 × 30 | 70 × 36 × 30 | 70 × 36 × 30 | | Weight | 35 kg (75 lbs) | 35 kg (75 lbs) | 35 kg (75 lbs) | 35 kg (75 lbs) | 35 kg (75 lbs) | | Max. Temp. | 80ºC (176ºF) | | Power | 110V/220V | | Cleaning | Flush to clean | | Application | Nano emulsion, fat emulsion, liposome, cell disruption, nano dispersion, deagglomeration | | Features | Digital display of pressure or pressure gauge | | | | Standard Features | | Parts | Y-type diamond interaction chamber with cooling option | | Control System | High pressure programming control systems: touch screen, speed control, auto stop control by volume, time, pressure or temperature, settable volume control as low as 1mL, display of flow rate and time, overload protection | | Pressure Gauge | Digital display on the touch screen | | Inlet Type | 1/4" HP coupling | | Outlet Type | 1/4" HP coupling | | Inlet Reservoir | 20mL syringe | | Outlet Reservoir | 20mL syringe | | Product Material | 316L stainless steel, tungsten carbide, viton, teflon | | Material Standard | Sanitary grade, FDA, GMP | | Warranty | 1 year against any manufacturing defects | | | | Option Features | | Parts | High pressure extruders, homogenizing valves two stages, heat exchanger | | Control System | Mechanical control: speed, start, stop control | | Detector | Pressure gauge, pressure transducer, temperature transducer | | Outlet Type | Tri-clamp or luer | | Heat Exchanger | HPE-100-3D; HPE-150-3D; HPE-200-3D | | Liposome Extruder | GOE-200mL; GOE-1000mL | | Inlet Reservoir | 10mL, 20mL, 50mL, 100mL, 200mL, 500mL syringe, S/S cylinder, jacketed glass cylinder or online | | Outlet Reservoir | 10mL, 20mL, 50mL, 100mL, 200mL, 500mL syringe, S/S cylinder, jacketed glass cylinder or online | | Cylinder | Titanium high pressure cylinder (resistant to strong acid and base) | | | Product Introduction and User Guide Video Sharing:

user guids of genizer highpressure homogenizers

Introduces the structure and operation of the microjet high-pressure homogenizer |

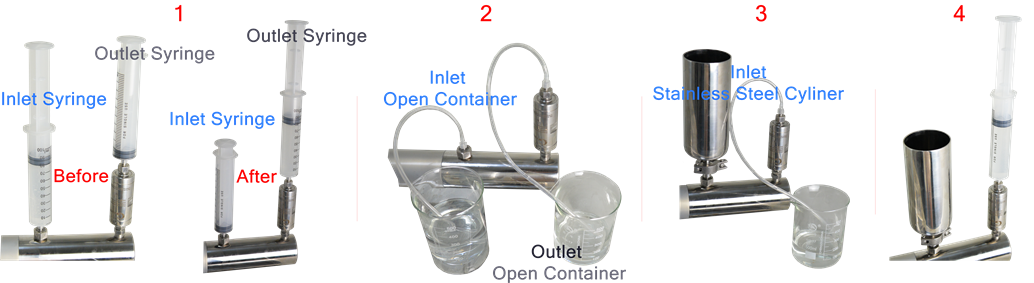

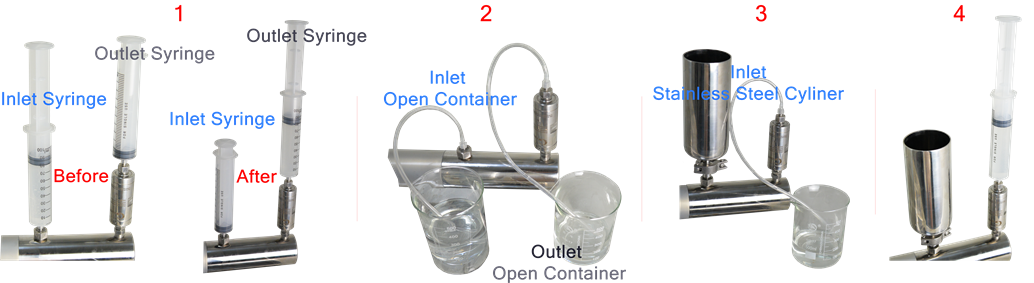

Varieties of Inlet and Outlet for NanoGenizer Inlet: syringe; open container; stainless steel cylinder

Outlet: syringe; open container; stainless steel cylinder

Genizer Diamond Interaction Chambers for High Pressure Homogenizers

Y-Type Diamond Interaction Chamber (DIXC) is used to produce uniform nanoparticles in a high pressure homogenizer. The fixed geometry within the Y-Type DIXC is intended to create a uniform processing profile so that all materials will be processed with equal disruptive forces. Single-slotted interaction chambers have a single microchannel and are ideal choices for small batch research, while the multi-slotted interaction chamber comprises multiple microchannels in parallel, which can be used at industrial scales, by increasing the flow rate through the DIXC but with equal processing forces. | | | | Application: | | Nanoemulsion, cell disruption, nanodispersion, deagglomeration, liposome | | | | Performance: | Full replacement for the chamber of Microfluidizer processors

Electro-polishing and inner passivation for pharmaceutical applications

Real-time cooling option to reduce oversized particles

Lower cost and higher quality | | | | Specifications | | Description | Y-type diamond interaction chamber single-slotted, multi-slotted | | Brand | GenizerTM with high quality | | Compatibility with Microfluidizer, Avestin EmulsiFlexs, PSI | Single-slotted: M-110Y, M-110P, M-110L, M-110S and M-110EH, PSI-20, adapt to Avestin EmusiFlxe-C3

Multi-slotted: M-7115, M-7125, M-7250, M210, M610, PSI-40 | Dimensions

W × D × H | 35mm × 35mm × 85mm (single-slotted)

45mm × 45mm × 200mm (multi-slotted)

95mm × 95mm × 300mm (9/16" F→9/16" M multi-slotted) | | Weight | 1 lbs. (0.5kg) (single-slotted)

3 lbs. (1.5kg) (multi-slotted)

15 lbs. (7.0kg) (M610) | | Cleaning | Flush to clean | | Sterilization | Whole unit autoclavable | | Pressure Range | 20,000 psi; 30,000 psi; 45,000 psi | | Chamber Type Available | Single-slotted: F12Y, F20Y and static homogenizing valve

Multi-slotted: F12Y-4, F12Y-5, F12Y-6, F12Y-7, F20Y-2, F20Y-4, F20Y-6, F20Y-7, F20Y-12, F20Y-13, F20-Y-17 | | | | Standard Features | | Chamber Type | Y-type diamond interaction chamber:

F12Y, F20Y, N40Y, J30Y, J20Y for M210,

F30Y, H230Y, F20Y-12, F20Y-13, F20-Y-14 for M610 | | Max. Pressure | 30,000 psi | | Product Material | 316L stainless steel, diamond | | Polishing Condition | Electro-polish and passivation for pharmaceuticals | | Warranty | 1 year against any manufacturing defects | | | | Option Features | | Chamber Type | Z-type diamond interaction chamber:

H10Z, G10Z, H30Z, H210Z, H230Z, Q50Z, T50Z, T60Z, APM

diamond auxiliary processing modules (APM) | | Customer Made | Customized laser mark, dimensions and fittings | | Max. Pressure | 45,000 psi | | Product Material | Titanium (resistant to strong acid and base) | | Product Cooling | Real time cooling on chamber | | | Upgrade to Y-Type Diamond Interaction Chamber | Upgrade used F12Y or F20Y chamber to F12Y-RT or F20Y-RT diamond chamber with real-time cooling function. Promotion available for a limited time. | | | | Original Chamber | Upgrade to Brand New | Price | | F12Y or F20Y diamond single-slotted chamber | F12Y-1-RT or F20Y-1-RT diamond chamber | Quote | | F12Y or F20Y ceramic single-slotted | F12Y-1-RT or F20Y-1-RT diamond chamber | Quote | | F12Y or F20Y multi-slotted chamber | F12Y-RT or F20Y-RT multi-slotted diamond chamber | Quote |

| Description: | | The HandExtruder is a manually powered extruder designed for the formulation of 0.25mL-2.0mL liposome and lipopolyplex with small samples. The sample is passed back through the membrane by being pushed back and forth between two syringes. Homogenous samples can be produced quickly and easily in minutes; typically 5-10 passes are sufficient to produce a sample with uniform liposome size. The HandExtruder offers minimal dead-volume, is easy to clean and is suitable for sterilization. Temperature control is available. | | | | Application: | | Liposome extrusion | | | | Performance: | Low dead volume

HandExtruder-1mL-RT can increase the temperature | | | | Specifications | | Catalog No. | HandExtruder-1mL | HandExtruder-1mL-RT | | Description | Liposome hand extruder | Liposome hand extruder with thermo-jacket | | Cooling | None | Yes | | Dimensions | 23cm×17cm×13cm | 23cm×17cm×13cm | | Weight | 2kg | 2kg | | Application | Liposome formulation | Lipids with high transition temperature or heat-sensitive | | Min. Sample Size | 0.25mL | | Max. Pressure | 700 psi | | Temperature Limit | 80ºC (176ºF) | | Power Type | Manual | | Nano-membrane | 19mm polycarbonate membrane | | Cleaning | Flush to clean | | Sterilization | Whole unit autoclavable | | | | Standard Features | | Parts | 1) Liposome HandExtruder

2) 10 pieces of 100nm/400nm/other size membrane | | Feed Reservoir | 1.0 mL gas-tight syringe | | Collector Reservoir | 1.0 mL gas-tight syringe | | Nano Membrane | 100nm 19mm track-etched polycarbonate membrane | | Compatibility | Parts are compatible with Liposofast in Avestin | | Product Material | 316L stainless steel, viton | | Material Standard | Sanitary grade | | Warranty | 1 year against any manufacturing defects | | | | Option Features | | Parts | Stabilizer holder for HandExtruder | | Feed Reservoir | 0.25/0.5/1.0/2.5mL gas-tight syringe | | Collector Reservoir | 0.25/0.5/1.0/2.5mL gas-tight syringe | | Nano Membrane | 30, 50, 80, 100, 200, 400, 800nm, 1000nm, 2μm, 5μm, 10μm, 20μm, 30μm 19mm track-etched membrane | | Syringe Type | Gas-tight syringe with protective film | | | Product Introduction and User Guide Video Sharing:

Introduction of HandExtruder

How to make liposome with HandExtruder |

|

|

Comments

Post a Comment