How to choose a high pressure homogenizer for your applications?

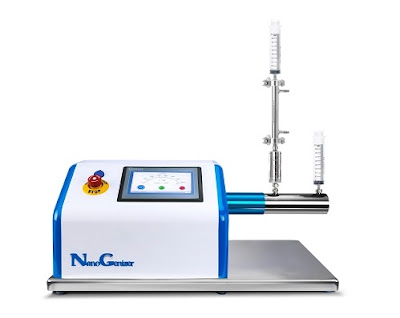

High-pressure homogenizers play a pivotal role in various domains, including scientific research, pharmaceutical manufacturing, cosmetics, and food processing. Opting for an appropriate high-pressure homogenizer is crucial to ensure optimal experimental outcomes and resource efficiency. Here are several key factors to consider when selecting the most suitable high-pressure homogenizer: Genizer High Pressure Microfluidic Homogenizers 1. Homogenization Pressure: Maximizing Performance by Optimizing Pressure Increasing pressure allows for finer particle size reduction, enabling efficient processing. Higher pressures accommodate a broader range of materials for effective homogenization. For example, certain liquid emulsions require a minimum pressure of 15,000 psi to achieve sub-100nm homogenization, while achieving nanoscale homogenization for pharmaceuticals, foods, and suspensions with solid particles typically demands pressures exceeding 26,000 psi. ...